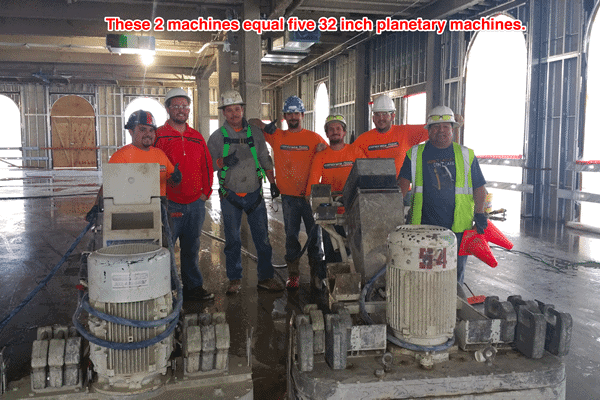

As with most construction projects, getting this job done quickly while maintaining the quality was paramount. The project was very delayed by the wet weather Denver received over the summer. This put the project behind schedule giving us over 60,000 square feet to do in a hurry. In order to accommodate the schedule, we brought in our large 60-inch machines that weigh over 1,800 lbs. The weight gives a great polish due to the head pressure on the diamond and the concrete.

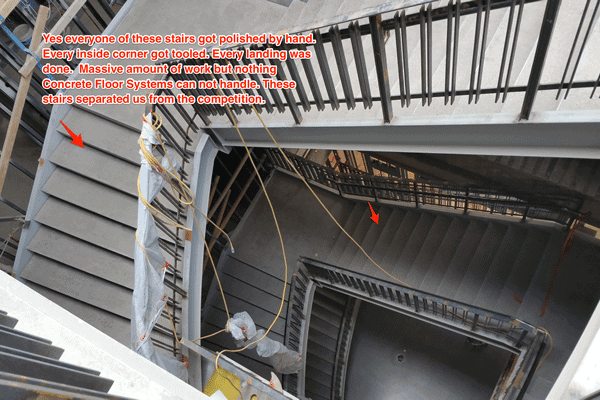

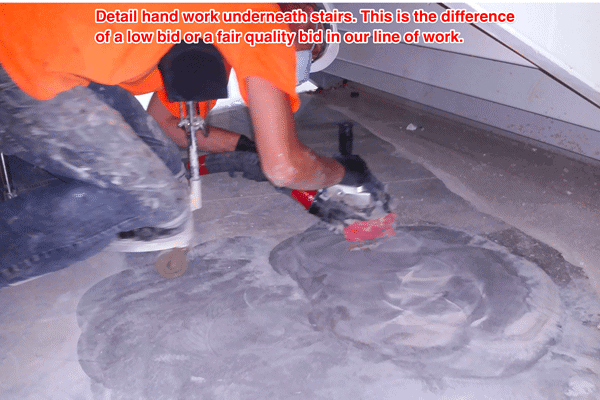

Restoration Hardware wanted all of their stairs hand polished. As you can imagine, this was a massive undertaking. The hand units could not get into the inside corners so those had to be done with a very small tool that could get into the corners. This was very time consuming but required in order for everything to blend.

Many companies skip these steps in order to save 33% less time but the end result will not blend and then decreasing the quality of the results. Responses you will hear from other companies will include things like “ You can not get in those corners with a hand unit….” This is true but there are other tools that can get inside those corners.

Large construction projects like this always come with challenges on the job requiring good, fast problem solving, this is exactly what we are known for. The contractor did not have the roof dried in allowing multiple floods across the floor throughout our polishing process. This is normally not an issue after the floor is polished, however, during the process of concrete polishing it will cause efflorescence issues.

This happens when the concrete is very green and water puddling will bring the natural salts in the concrete up to the surface. This looks like white spots. As soon as the rain started, we notified the prime general contractor to let them know of the issue. We had to stop polishing due to the massive amount of water flowing into the building.

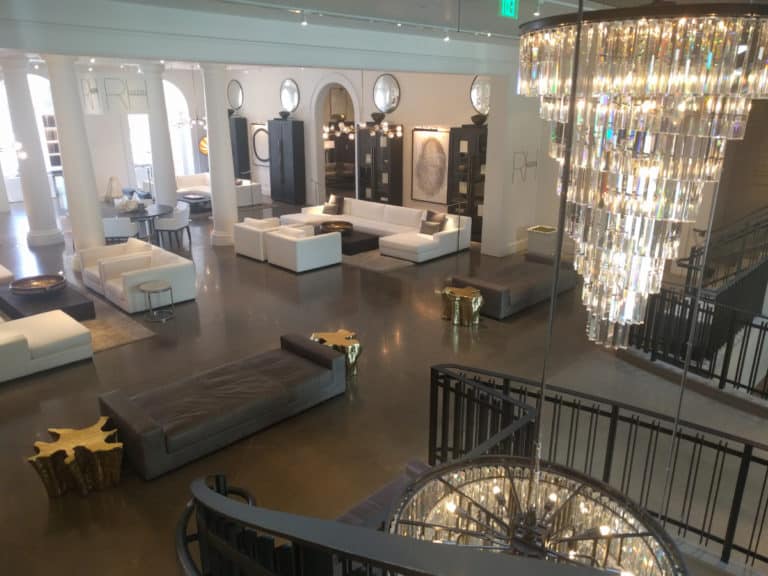

After another delay in the schedule due to the roof issue, we had to reschedule this job when the conditions onsite were more favorable for polishing. Even with the roof and weather delays, we made all needed repairs from the water, completed all work within our scope on schedule and the end product was beyond the owners expectations!!!

Restoration Hardware has had countless issues with other polishers when it comes to getting the end results they wanted, keeping the high quality product and staying within a strict timeframe. They wanted a high-end cream polish with a satin finish. They wanted all edges done and all repairs done with a very high quality. This was the reason we were hired. Once the floor was complete, people from all levels at Restoration Hardware believe this is the best floor amongst all of their stores nationwide!!!