Key Takeaways on Dry Pour Concrete

We know you’re busy and we encourage you to read the entire article, but if you don’t have time, be sure to bookmark the article and read our summary below:

With Dry Pour Concrete, Water is Not Mixed With Concrete, it is Poured on top of an existing concrete mix that has already been placed in a form.

With the dry pour method, you pour dry ingredients into the desired area and add water later. Unlike wet pour concrete, dry pour omits water until it’s ready for use.

Tool Requirements are Fairly Simple: Trowel, Mixer, Formwork

You’ll need the right tools for dry pouring, including a mixer, trowel, screed and formwork. The form holds the concrete in place as it dries.

Water is Still Used in Dry Pour Concrete

Don’t confuse dry pour with a lack of water. You still need water to give concrete its strength. The difference is in when you’re adding the water. With dry pour, you have more control over the process.

For Your Dry Pour Concrete to be Effective, You Must Have Exact Ratios of Ingredients

In terms of materials, concrete requires cement and aggregate. You must combine these ingredients to form the structure and durability of the final product. Accurate ratios are crucial to ensure the desired strength and quality. Excess water – or not enough water, can create serious problems with your concrete installation and may even result in a failed project.

Dry Pour Concrete Should Only be Used in Very Specific, non Weight Bearing Applications

Keep in mind that dry pouring isn’t for every situation. Some may use it for small slabs that don’t bear much weight, like the entrance to a tool shed in the video below. But even those applications come with risk of having to tear the concrete out and start over with a new slab if it isn’t done properly. For larger slabs that must endure heavy foot traffic or vehicle traffic, wet pour concrete is always the better choice.

Dry Pour Concrete Looks Different

Lastly, remember that the appearance of dry pour surfaces might differ from those of wet pour. It’s essential to choose the right method based on your specific project and its requirements.

Dry vs Wet Pour: Comparing Techniques

When deciding between dry and wet mix concrete, consider the consistency of the final product. When pouring concrete that is wet, you’ll achieve a more uniform mixture because water is added during the mixing process (usually within a concrete mixer). This ensures better quality and strength in the final product when compared to dry mix concrete.

On the other hand, dry pouring involves mixing dry ingredients like cement, sand, and aggregates separately in the proper ratios. You don’t add water until the very end at the job site.

In terms of cost-effectiveness, dry pouring has its advantages. It typically requires less manpower and can lead to faster curing times, which is crucial for projects with tight deadlines. However, this method really isn’t ideal for most projects.

Dry Pour Concrete Should be Avoided for All but the Most Limited Concrete Applications

You’ve probably heard the saying “good, fast, cheap – pick two”. Dry pour concrete is certainly fast and cheap, but it isn’t that good – meaning it isn’t all that durable.

Wet pour concrete tends to have better strength and durability. As a hardened concrete, it is less likely to chip or crumble under stress.

The strength of dry poured concrete isn’t nearly as good as what you can get with properly mixed wet concrete. This leaves dry pour concrete as an option for only the most limited, less mission-critical applications.

Mixing, Pouring and Curing Process

When dealing with dry pour concrete, it’s essential to know the proper steps for mixing, pouring, and curing. Let’s dive into the process.

First, you’ll need to mix your concrete. Begin by combining your cement and other dry ingredients in the proper ratios. Ensure that the consistency is even throughout the mixture. If you’re unsure about the correct ratios, consult the manufacturer’s recommendations.

After preparing the dry mix, pour it into your desired area. Make sure the formwork you’ve set up is strong and well-secured to hold the concrete. Spread the dry mix evenly throughout the form. Remember that this method requires specialized equipment such as a mixer, trowel, and formwork.

Once the dry mix is in place, add water using a hose. The key here is to achieve a consistent hydration throughout the mixture. The right consistency is crucial for a strong structure. Too wet, and you run the risk of weakening the concrete; too dry, and it won’t bond properly.

After adding water, use a screed board to level and smooth the surface. Achieving an even surface helps minimize issues like cracks and uneven settling.

Next, let the curing process begin. This critical step involves the hydration process, which allows the concrete to harden and gain strength. Drying time for a concrete slab typically takes about 2 days. Concrete cure time is considerably longer – up to four weeks.

When curing concrete, monitor the moisture levels and temperature closely. Excess heat, cold, or moisture can have adverse effects on your concrete. Proper curing delivers a durable and robust final product.

Advantages and Disadvantages

Dry pour concrete offers you several advantages and disadvantages to consider in your construction projects.

Dry Pour is a Bit Easier

First, it is a bit easier to just pour the dry concrete directly into the form that you’ve created for your slab and just add the water on top at the end. It also sets extremely quickly if you’re using a mix like quikcrete.

Dry Pour is Lower Quality

However, there are some trade-offs you should consider. Despite the time-saving factor, dry pour concrete might not be as cost-effective in the long run. Higher labor, maintenance, and materials costs may offset the initial time saved. If your dry pour slab fails, placing a new concrete slab to replace it with a more durable concrete slab can be expensive.

Dry Pour Requires More Maintenance

In terms of quality, wet pour concrete’s durability and consistency are key advantages. A dry pour may lead to increased risks of cracking or uneven surfaces. This can lead to the need to frequently patch the concrete or eventually even replace the slab.

Your budget plays a significant role in deciding whether to use dry pour or wet pour methods. Dry pour might be ideal if you’re after time-saving benefits and looking to save money in the short term. On the other hand, wet pour can be more cost-effective in the long run due to its durability when compared to dry pour.

Dry Pour Concrete Backyard Project

The Challenges of Working with Dry Pour Concrete to Create a New Concrete Slab

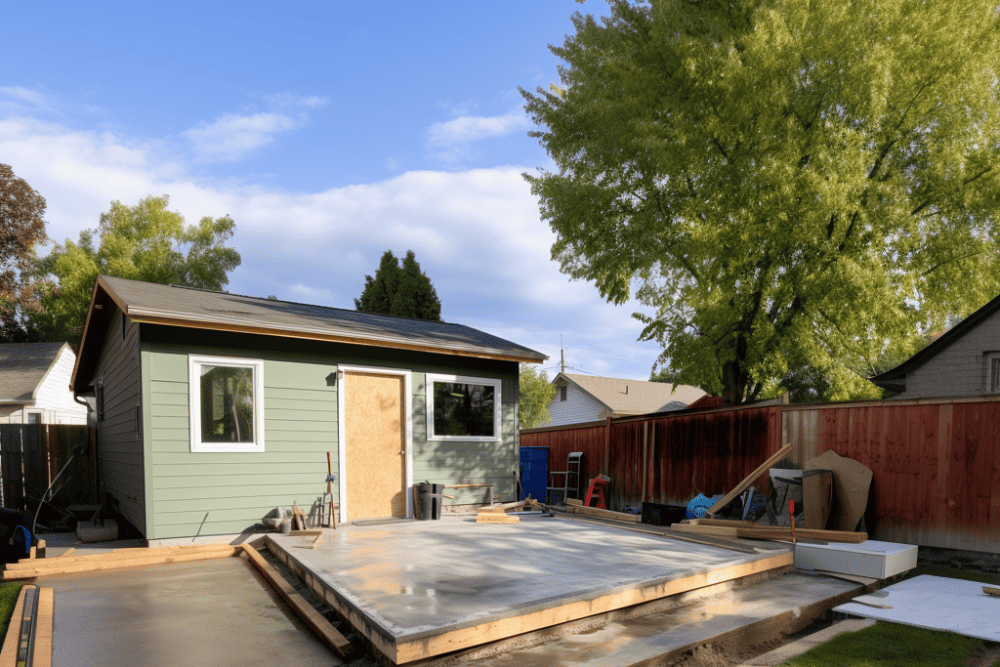

Thanks to DIY Homestead Projects for the above video. They ran into quite a few problems when putting together a concrete slab in front of their backyard shed. The troubles they encountered aren’t unusual when working with dry pour concrete.

Issues they ran into:

Slab Appearance

To start their concrete project, they laid down their dry mix and leveled it as much as possible. They had difficulty coming up with a smooth, powdery finish on the surface of the concrete slab. The appearance of dry pour concrete is usually much different than wet pour concrete, and their attempted fix to this problem by adding Portland cement may have made the situation worse. Portland cement is meant to be part of a wet concrete mixture – not a dry pour project.

Tools

When performing DIY projects, you not only don’t have the same experience as concrete pros, you also don’t have access to the same tools that concrete professionals have. In this case they didn’t have a true screed, instead they used a 2×4 that was somewhat warped. This prevented them from achieving a true level surface.

Hairline Cracks

Unfortunately, after the concrete curing and drying process, the slab had many hairline cracks. While the cracks were along the concrete surface and didn’t go all the way through to the base, they may represent an entry point for water which can damage the slab and expand and deepen the cracks – especially during thaw freeze cycles. The cracks and crumbling are indicative of some potential concrete strength issues that could result in bigger problems with the slab in the future.

Inexperience

Working with concrete is extremely challenging, especially if you’re not a concrete contractor. Even for folks who are very handy, working with concrete can result in mistakes leading to a failed project.

Don’t Start a Major Concrete Installation When Rain is Expected

Rain can significantly impact both wet mix and dry pour concrete by disrupting the curing process and altering the water-to-cement ratio. For wet mix concrete, rain can dilute the mixture, leading to a weaker final product with reduced structural integrity. The excess water can cause the concrete to become too fluid, resulting in poor surface finish, increased porosity, and potential cracking as it dries unevenly. Additionally, rain can wash away the cement paste from the surface, exposing the aggregate and compromising the concrete’s strength and durability.

For dry pour concrete, rain can prematurely activate the curing process before the mix is adequately combined and placed. This can lead to uneven hydration and weak spots within the concrete. Since dry poured concrete relies on water being added after placement, unexpected rain can disrupt the intended water distribution and overall ratio, causing some areas to remain dry while others become overly saturated. This inconsistency can result in a structurally unsound final product, with potential for cracking, erosion, and reduced lifespan.

Frequently Asked Questions

What is the difference between wet concrete and dry concrete?

Wet concrete is a mix of cement, sand, aggregate, and water. It is a fluid mixture that can be poured and molded into desired shapes. Dry concrete, on the other hand, is a blend of cement, sand, and aggregate without water. You add water to dry concrete on-site after it is placed within a containing form.

Is Dry Pour Concrete a Good Idea?

While you may save a bit of time and money in the short run with dry our concrete, wet pour concrete is preferred for most projects because it is stronger and more durable. Dry pour should be used in only the most simple projects that require minimal compressive strength of your concrete slab.

How strong is dry pour concrete?

Dry pour concrete is typically not nearly as strong as wet pour concrete and can’t stand up to weight bearing applications nearly as well.

Can dry pour concrete be used for fence posts?

Yes, you can use dry pour concrete for fence posts, but you would likely have much better results with wet pour concrete. It is better to mix the concrete with water before pouring it around the post to ensure a strong and stable footing.

Is dry pour concrete suitable for walkways?

Is dry pour concreteDry pour isn’t ideal for consistent weight bearing applications like walkways. Wet pour concrete is typically considered a better choice due to its higher strength and durability. suitable for walkways?

Can I use dry pour concrete for my driveway?

Dry pour concrete has limited compressive strength and is best used for very limited applications like fenceposts and small non weight bearing concrete slabs. Use wet pour for concrete driveways.