Project Summary

The general contractor brought us in for this polished concrete project for Cherry Creek School District. The building itself is a technical school located in Centennial CO. The job involved our CFS patented concrete polishing system on an elevated deck that had a massive amount of cracks in the slab – while at the same time making it durable and low maintenance free for years to come. The first level slab was elevated as well with no control joints with cracks everywhere. All of those had to be fixed with our proprietary process of backfilling the floor with a matching color.

Project Highlights

- Polished and stained 48K square feet

- Sealed concrete 23K square feet

- 2 sets of polished stairs

- 5 sets of sealed stairs

- Elevated concrete slab

- Concrete slab on grade with cracks everywhere

Project Details

Project Details

This job was performed and completed in the summer of 2019. The general contractor had to shorten the duration from 10 weeks to 5 weeks. Due to the size of Concrete Floor System’s 14 crews, we were able to double up teams to get this job done on the GC’s hyper-speed schedule.

Where

Centennial, CO

Client

Cherry Creek School District (we were subcontractors to a general contractor)

Before

Cracks on an Elevated Concrete Deck

The biggest challenge we had to deal with on this project was a slab on an elevated deck.

Elevated concrete slabs that we deal with usually come in three categories:

- Structurally reinforced concrete slab

- Concrete slab composite with a steel deck

- Concrete slab on a steel deck

This particular project fell into the last category – a concrete slab on a steel deck.

As can happen with elevated slabs, this slab was riddled with extensive cracking, microfractures, and pinholing when we arrived on the scene. As always Concrete Floor Systems has a solution to create an amazing product even with all the cracks in the slab. Cracks in elevated decks are due to three main factors:

- Concrete volume shrinkage due to drying and hardening

- Contraction due to ongoing temperature changes within the facility

- Deflection on the slab

This was a problem that needed addressing. Aesthetically, cracks in the concrete were an obvious problem. The cracks were numerous and would detract from the otherwise amazing modern, high-tech feel of the school.

You can actually see the intersecting cracks in the photo below.

But it wasn’t just aesthetics we were concerned about. If left unchecked, cracks in elevated concrete decks can lead to many other problems. Untreated cracks can cause problems even if they don’t directly impact the structural integrity of the concrete slab. These cracks can widen and open the door for moisture and other environmental factors which could eventually compromise the slab and underlying structure.

Spalling / Pinholing on the Concrete Deck

In addition to the cracks, the concrete also had extensive spalling. Spalling is when pieces of the surface of the concrete flake away. Spalling is usually associated with moisture in the slab trying to escape. It appears as obvious oval or circular shapes on the surface of the concrete. You can see the extent of the spalling in the photo of the concrete slab below.

We needed to take care of the spalling and restore the deck to a beautiful, uniform concrete surface.

Ground Floor Concrete Slab on Grade

This project also featured concrete on the ground floor of the facility. Fortunately, this concrete was in better shape than what we were dealing with on the elevated deck, but it still needed to be repaired and polished.

The Solution

To remedy this problem the building owner (Cherry Creek School District) was left with a few different options:

- Rip out and replace the existing concrete slab

- Put down a vinyl covering on top of the vinyl

- Repair and Polish the Concrete Floor

Each of these options are explained below:

Rip Out and Replace

A rip out and replace of the concrete slab would have been prohibitively expensive for our client. This really wasn’t a viable option.

Vinyl Covering

This is where many property owners make a bad decision. Placing a covering on the floor really doesn’t fix the problem. In the short term, it may not be as expensive as repairing and polishing, but there are significant maintenance costs involved with using floor coverings (such as vinyl) on concrete. This makes vinyl covering a more expensive option – not to mention much less aesthetically pleasing than polished concrete.

Repair and Polish the Concrete Floor

This was far and away the right choice. By rehabilitating the existing concrete slab, the property owners saved an estimated $7 / Square foot in the lifetime cost of the floor. Polished concrete is extremely inexpensive to maintain when compared to other flooring options.

The property owner made the right choice, and we were brought in to repair and polish the elevated concrete slab.

The Process

While we pride ourselves on the ability to get our jobs done on schedule – as we did in this case – it is even more important to take the time to get the job done right. When we complete a concrete floor, other than occasional cleaning with a scrubber, it will be extremely low maintenance for years to come.

Concrete Color Matching

The process started with finding a perfect color match for the existing concrete slab. After doing five different color mock-ups to see what backfill color would best match the existing concrete color, we found one that was a perfect match.

Concrete Grinding (pre-Backfill)

We then started the grinding process. The first part of the grinding involves opening up the existing cracks in the floor.

Concrete Backfill

Next comes the backfill process, which was extensive. All cracks that were created from the movement of the deck were filled – as were all small pinholes in the concrete. We use a proprietary backfill product to ensure long-lasting results.

Concrete Grinding after Backfill

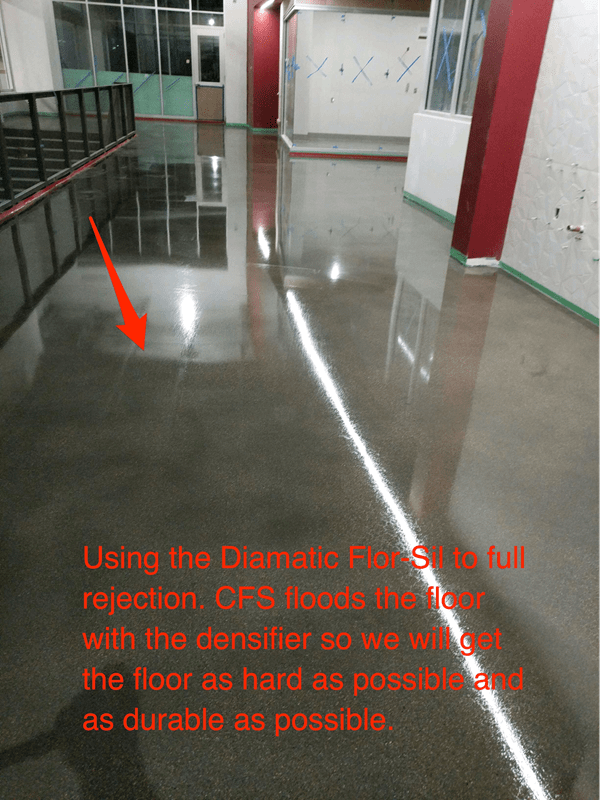

After the concrete was backfilled, we ground off the Concrete Floor Systems backfill system for us to start the concrete polishing. This job was polished to an 1800 grit finish high gloss finish. We densified the concrete twice to make the concrete extremely hard and durable.

Completed - Photo Gallery

You can see the finished product in the photos below

Sealed Concrete

After the concrete was backfilled, we ground off the Concrete Floor Systems backfill system for us to start the concrete polishing. This job was polished to an 1800 grit finish high gloss finish. We densified the concrete twice to make the concrete extremely hard and durable.

Polished Concrete

After the concrete was backfilled, we ground off the Concrete Floor Systems backfill system for us to start the concrete polishing. This job was polished to an 1800 grit finish high gloss finish. We densified the concrete twice to make the concrete extremely hard and durable.

Stairs

After the concrete was backfilled, we ground off the Concrete Floor Systems backfill system for us to start the concrete polishing. This job was polished to an 1800 grit finish high gloss finish. We densified the concrete twice to make the concrete extremely hard and durable.

Capabilities to Meet Difficult Deadlines

Due to the time constraints that the school was experiencing, the amount of time we had to complete the job was cut in half. Fortunately, we have the processes and highly skilled manpower to accommodate schedule changes in most cases.

We were able to mobilize multiple crews from our company and get them on-site to get the job done and easily meet the accelerated schedule.

Accolades

This is a showcase piece for the school, the general contractor, and of course for Concrete Floor Systems. Architects from different parts of the United States have visited the school and the polishing job that was performed as inspiration for future projects.

As a result of the work performed on this job, we have been contacted by many other school districts within the state and have begun work on similar projects throughout the state of Colorado.

View More School Concrete Polishing Jobs

We provide our services to many schools each year. View more of previous work providing polished concrete in schools.